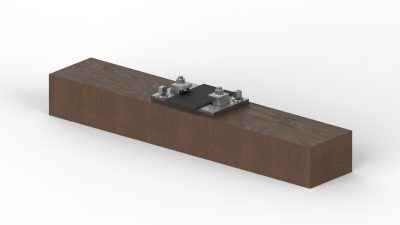

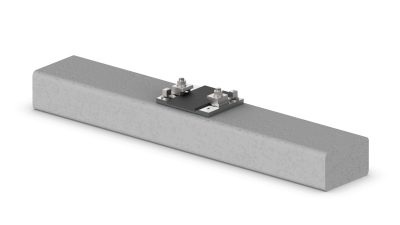

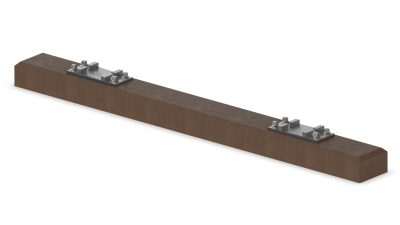

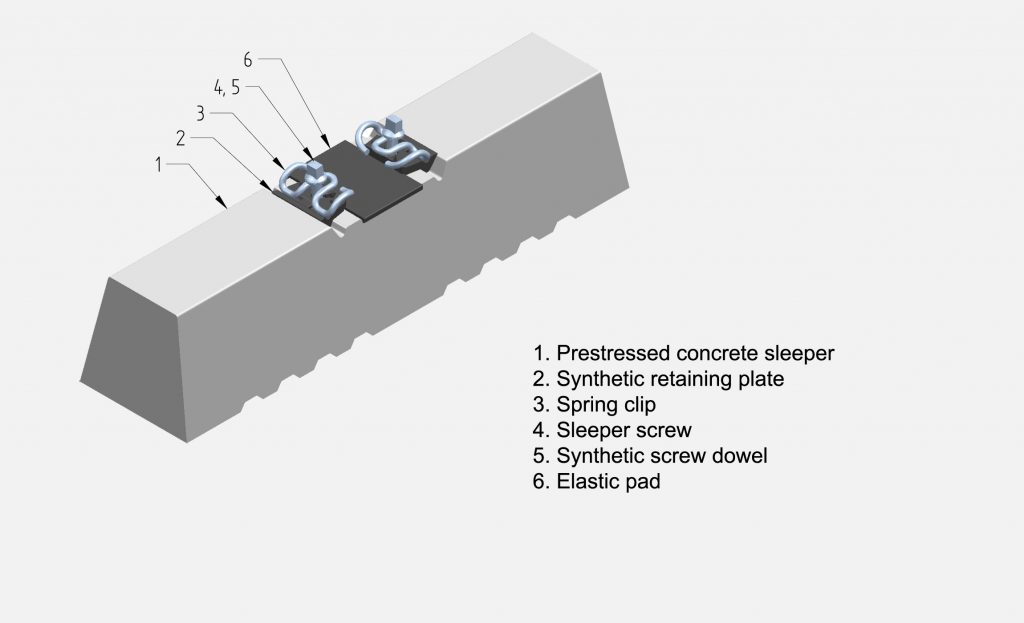

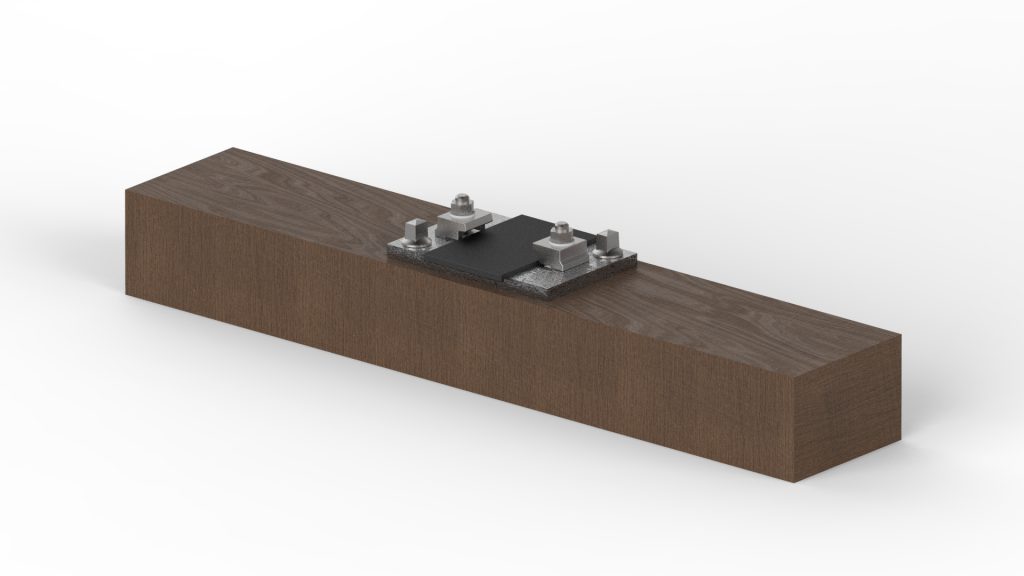

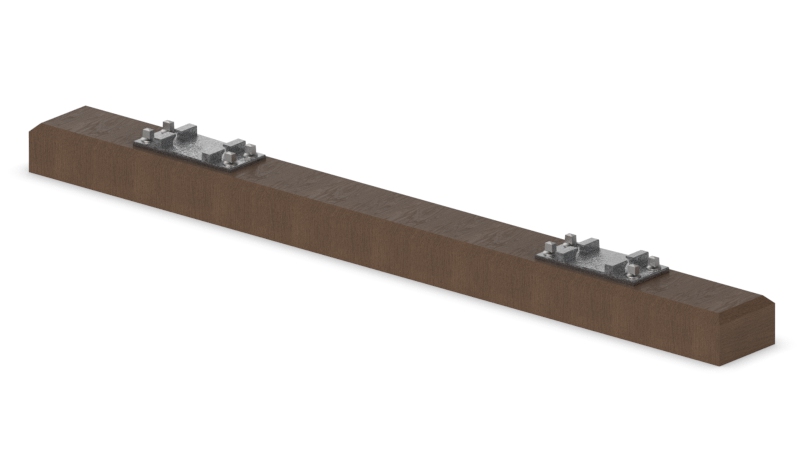

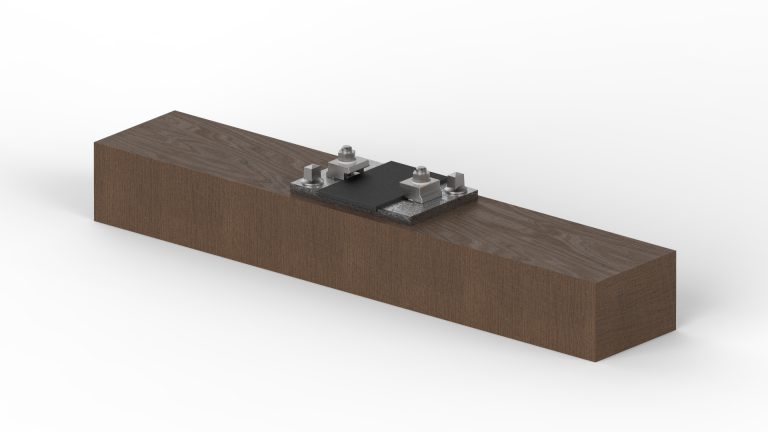

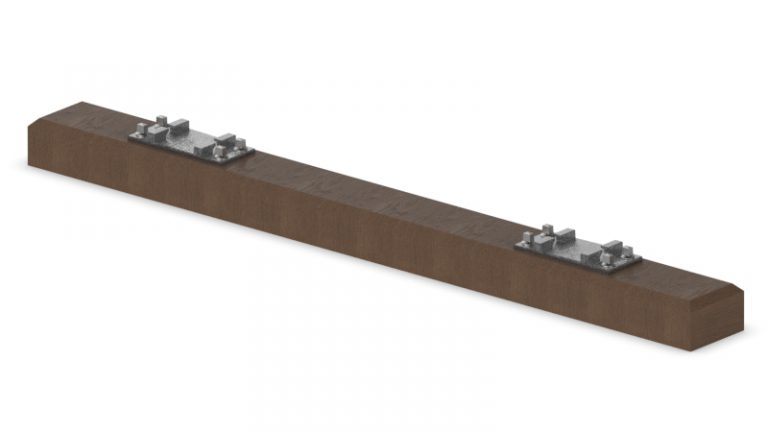

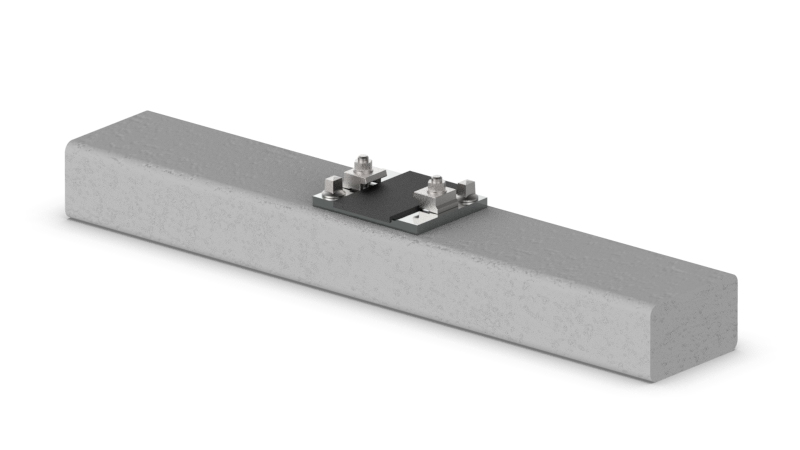

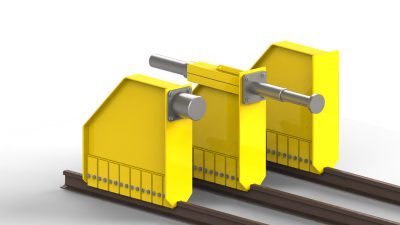

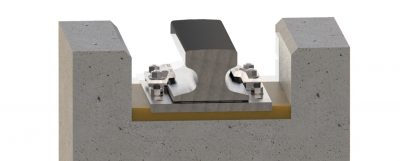

Sleepers, also known as sleepers or track girders, are part of the superstructure construction of crane tracks and railways. The sleepers support the rails and thus also the systems that run over them. It is important that the rails are stable and remain so. When stable a crane or train cannot derail and does not cause unnecessary vibration and noise. Sleepers do not reduce noise or vibration, but can cause a great deal of inconvenience if they deviate.

Contact with Bemo Rail about sleepers for rails

Click here for direct advice about crane track and railway sleepers