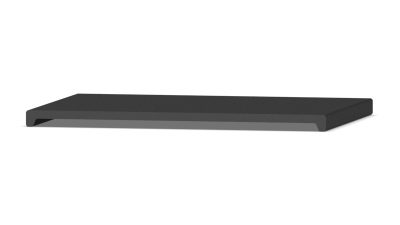

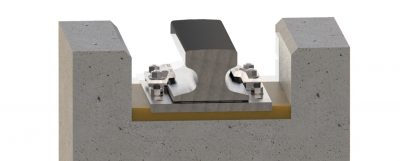

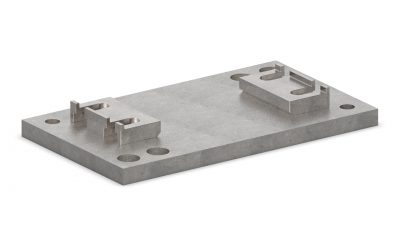

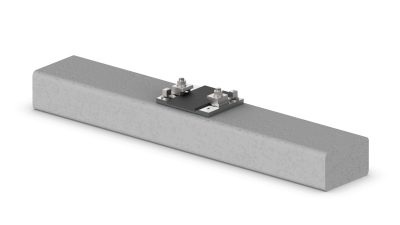

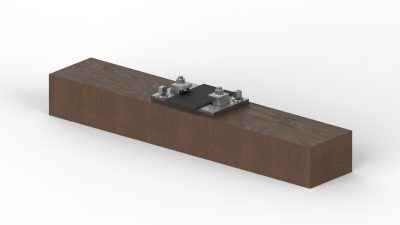

Elastic padding is mounted between the rail foot and the steel sole plate. We offer elastic material made of EVA and steel-reinforced rubber in various thicknesses.

Functions

Main functions of elastic underlay material:

- Better distribution of the load, over a larger surface.

- Preservation of the rail construction.

- Cancels point loads and the resulting fatigue.

- Absorption of contact irregularities between the rail and the supporting structure.

- Reduction of noise and vibrations.

- It minimises wear of the rail and sole plate.