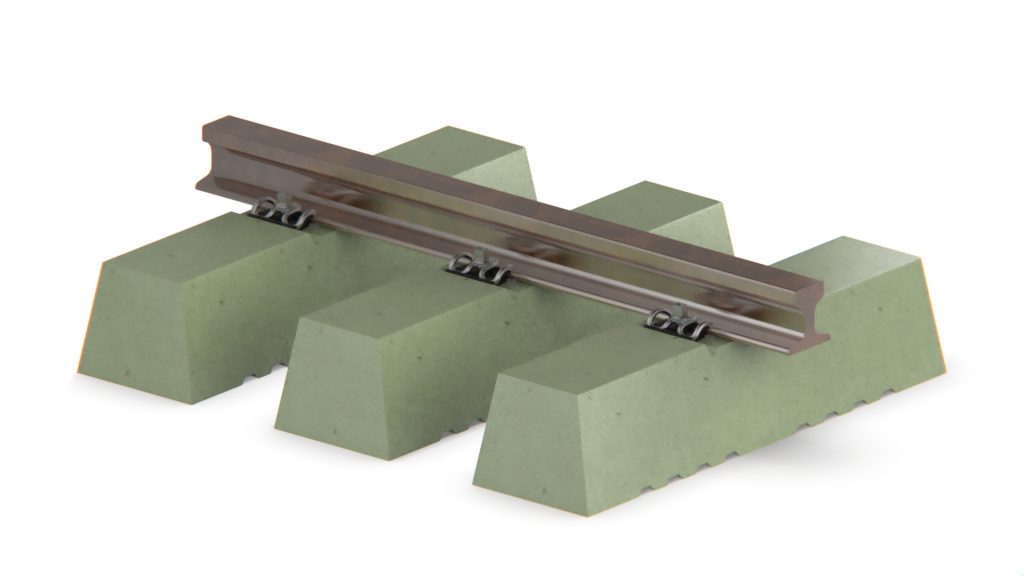

100% circular sleepers

Sulphur concrete is 100% circular, has low C02 emissions and does not lose quality. Remeltable concrete can be reused endlessly in identical applications with minimal impact on the environment.

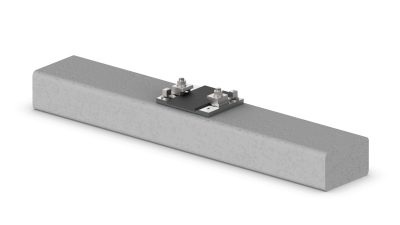

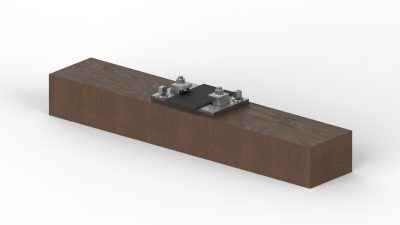

Concrete crane track sleepers are heavier than wooden or plastic sleepers and are therefore ideal for vehicles with heavier wheel loads. An additional advantage of concrete is its long service life of at least 40 years and low maintenance costs.

The product is similar to traditional concrete, with the cement and water being replaced by sulphur. Because of the production method of a concrete crossbeam, dimensional stability (within the set tolerances) is guaranteed.

Contact with Bemo Rail about sustainable crane track sleepers

Click here for direct advice about 100% circular crane track sleepers or download the brochure in pdf.