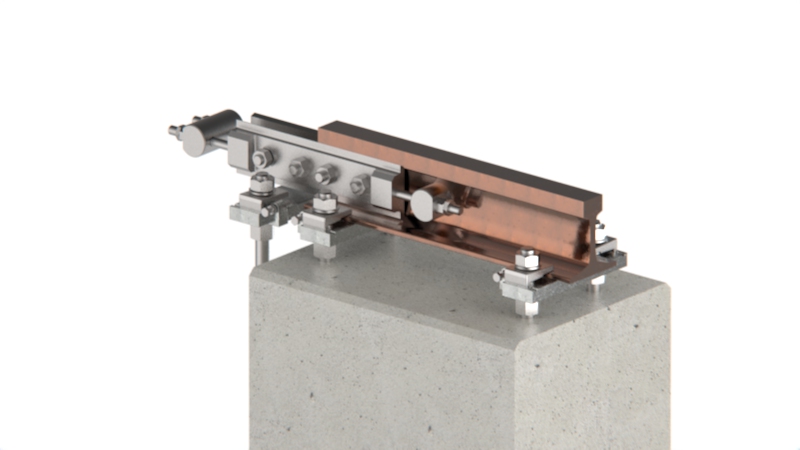

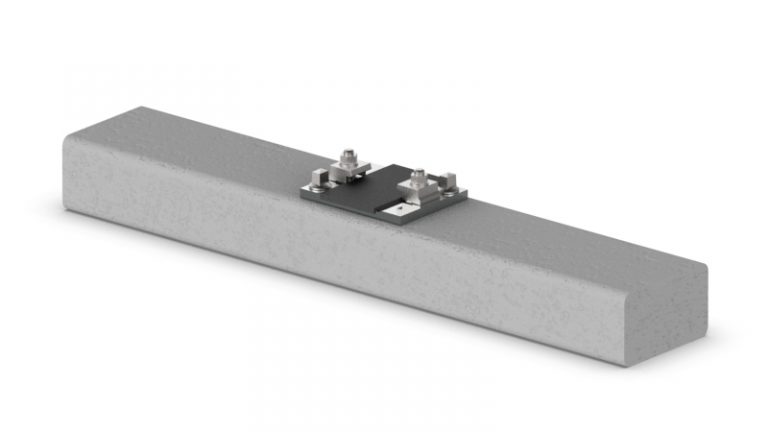

Concrete

With this system, the crane tracks and rail tracks are mounted on a concrete base.

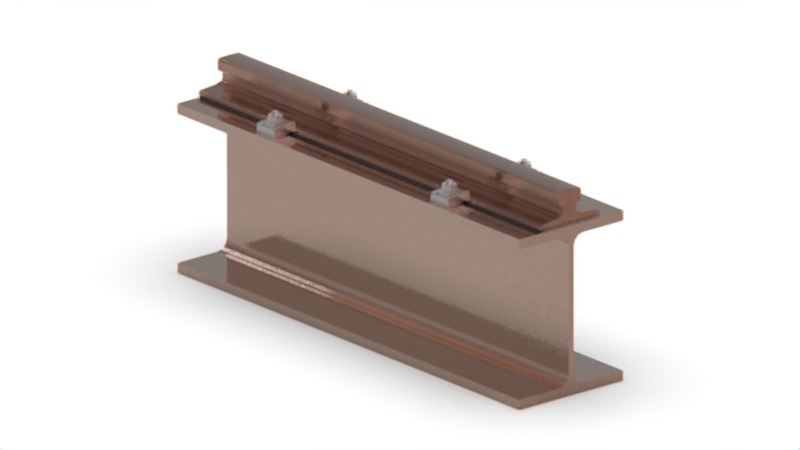

Steel

In this system, the rail constructions are mounted on a steel girder.

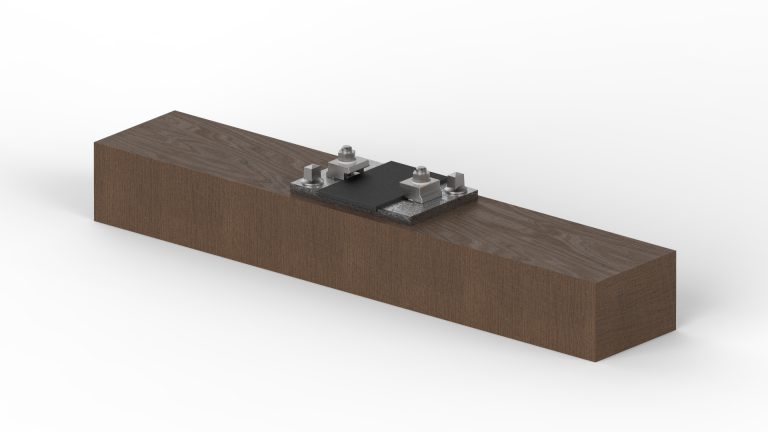

Ballast

This system is used on a ballast bed with sleepers of (sulphur) concrete, wood or plastic. The sleepers serve as a stable, strong base for the crane or rail track to be mounted on them.

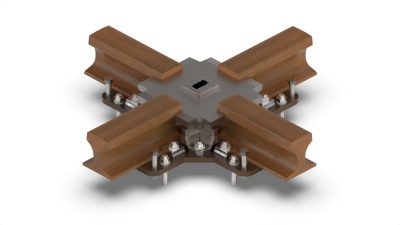

Special systems

Because of many years of experience, Bemo Rail can also design and deliver custom-made systems.

Find more information about our rail systems below.