Maximum gross trailing load: ca. 4,000 tons

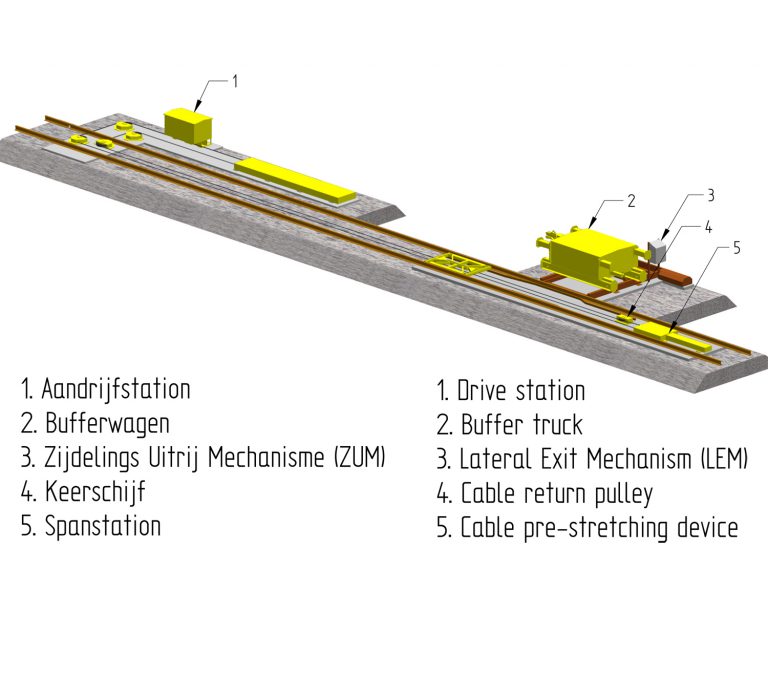

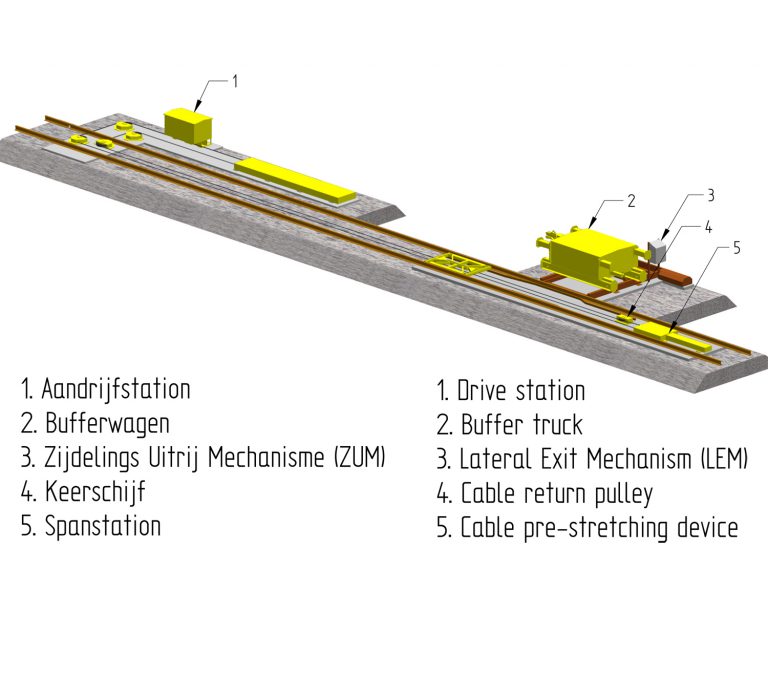

With this system a buffer truck is coupled to the central towing hook of the wagon. With this application the buffer truck can be coupled up and off automatically. The buffer truck moves on the same track as the wagons and is mostly applied at dead-end tracks. With this system the buffer truck cannot pass the wagons, but it can pass the switches.

This system can also be equipped with a so-called Lateral Exit Mechanism (LEM). By means of the LEM, the buffer truck leaves the track cross-wise. Which means that also here a ‘continuing track’ is created. The wagons can pass the system.

Wagon shunting systems require little maintenance, are energy and cost saving, efficient and safe.