Bemo Rail has been designing and producing shunting vehicles since the 1980s.

Road-rail vehicles are shunting locomotives that can operate both on rails as well as on the road and can easily switch between road and rail.

This vehicle has superb maneuverability, which is particularly convenient on sites with multiple independent track networks without a connection,

or when a connection point is too far away and transportation is faster by road.

Road-Rail vehicles

Bespoke road - rail shunter

This safe, modern, and user-friendly locomotive can be made in many versions. The road-rail vehicle is assembled from our standard components. Because of this modular construction, a road-rail shunter can be made to you requirements in terms of capacity, speed and traction.

Click here for direct contact with the experts of the shunting department.

See below for the technical options.

Technical options of the Bemo Rail shunting vehicles (click on the arrow to expand)

Shunting

- Continuously variable speed control from “0

- Smooth start off with favourable slip limit because of absence of peak forces.

Operation

- Standard Bemo locomotive control, designed for use under heavy-duty circumstances

- Vibration- and temperature-resistant

- Manual and/or radio remote control, if required within ATEX conditions

- Accelerating and braking according to fixed curves, as a result of which:

- The rail shunter always behaves and reacts steadily

- Incorrect control is nearly impossible

- Any operator should be able to work with the railshunter

Environmental and health & safety legislation

- Limited noise level

- Low fuel consumption

- Electric or hybrid drive

- Ergonomical accessibility for operation and service

Safety

- Emergency buttons on all corners of the machine, combined with radio remote control

- Integration of gas detection into the control unit,when used in ATEX conditions (optional)

- Security through additional proximity/reflection switches (optional)

- Excellent overview from the cabin

Control

- All shunting operations can be performed by one operator

- Easy to operate control system

- Clear graphic display for operating status and maintenance (HMI /GUI)

Mechanics

- High quality components are installed as a standard, such as an A-class engine

- Overall sprung axle suspension with fully closed reductors, resulting in:

- Reducing damage to switches

- Reducing the risk of derailment

- Long technical life span

- Short delivery time on spare parts

Maintenance

- Easily accessible, no special maintenance pit required

- Daily maintenance can be performed by in-housetechnical service

- Optimal set-up of intervals depending on the application

Shunting couplers

- All types of shunting couplers

- All associated adapters

- Automatic or non-automatic

Pneumatic systems

- Equipped with pneumatic system for (wagon) brakes

- Control of various components

- Compressor output, reservoir capacity and version are selected depending on the use of the locomotive

Track gauge

- Standard track gauge of 1435 mm

- Wide and narrow gauge possible

- Applicable worldwide

Shunting vehicles range

Shunting vehicles range

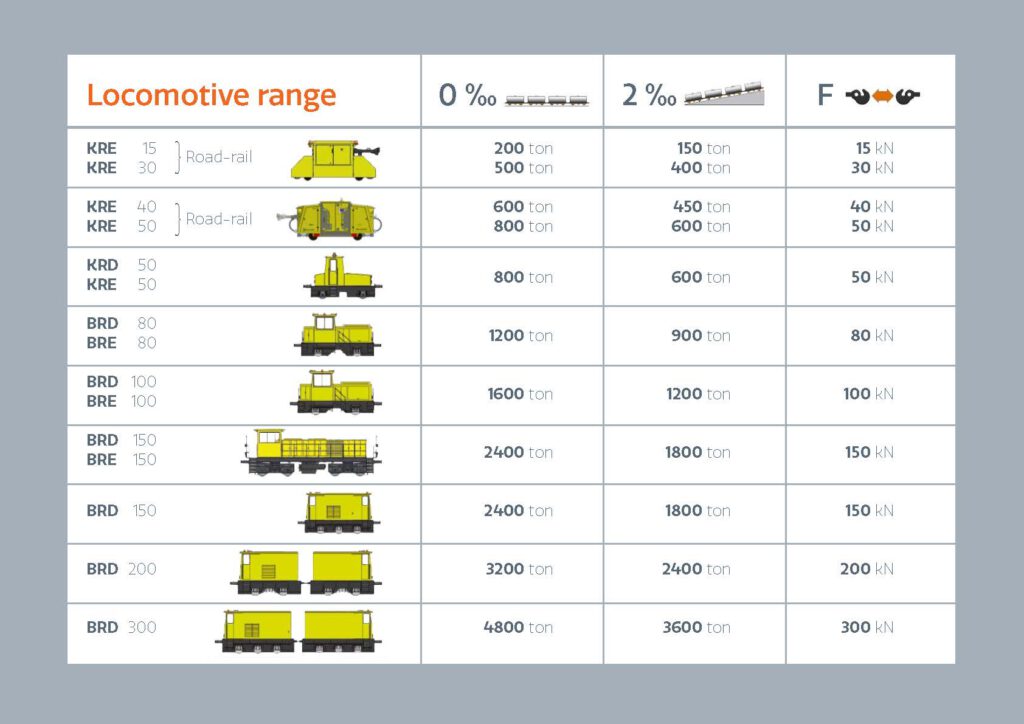

Bemo Rail offers various types of shunting vehicles, see the image of our locomotive range or click below for a larger image.

Basically, there are three drive options: hydrostatic or hydrodynamic drive with diesel engine, or an electric or hybrid drive. The locomotive can be operated either manually or by remote control. Our shunting locomotives can be built with a power of 10kN to 300kN and have a tensile strength varying from 50 to 4800 tons.

The Bemo Rail shunting vehicles are build from standard components. This modular construction, together with our in-house engineering department, a fully equipped workshop and full knowledge of rails and wagons enable us to adapt to your demands easily.

Request a proposal

Do you need advice from one of our technical specialists or would you like to recieve an offer for our products or services?

Fill in this contact form and we will contact you as soon as possible.

Or call us on:

+31 (0) 226 - 42 53 00.